LIDERROLL CREATES NEW METHOD FOR CONSTRUCTION OF SPOOL BASE THAT WILL REVOLUTIONIZE THE MARKET

After the innovation presented by Brazilian company Liderroll for the construction of a Spool Base, all the current bases which launch pipes into reel-lay vessels worldwide will appear to be medieval. The new construction method uses a technology that can reduce the welding time of the pipes, accelerate the launch to the reels of the ships, and considerably reduce the time that the vessel is anchored in the port, which is one of the costliest stages in the entire process. The project also foresees the use of solar panels for its own generation of energy. Moreover, this new method reduces the presence of workers and machines in the field, thus eliminating the risks of accidents and pipe damage. The currently known forms of construction utilize three, sometimes four, cranes that need to act in synchrony by carrying the pipe, which often gets damaged. In some cases, they need to have their welds redone, generating painful and expensive rework. Liderroll`s construction project can store 8 to 24 kilometers of 100% finished ducts, the equivalent of filling an entire spool of reel-lay vessels.

After the innovation presented by Brazilian company Liderroll for the construction of a Spool Base, all the current bases which launch pipes into reel-lay vessels worldwide will appear to be medieval. The new construction method uses a technology that can reduce the welding time of the pipes, accelerate the launch to the reels of the ships, and considerably reduce the time that the vessel is anchored in the port, which is one of the costliest stages in the entire process. The project also foresees the use of solar panels for its own generation of energy. Moreover, this new method reduces the presence of workers and machines in the field, thus eliminating the risks of accidents and pipe damage. The currently known forms of construction utilize three, sometimes four, cranes that need to act in synchrony by carrying the pipe, which often gets damaged. In some cases, they need to have their welds redone, generating painful and expensive rework. Liderroll`s construction project can store 8 to 24 kilometers of 100% finished ducts, the equivalent of filling an entire spool of reel-lay vessels.

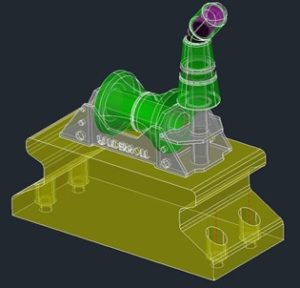

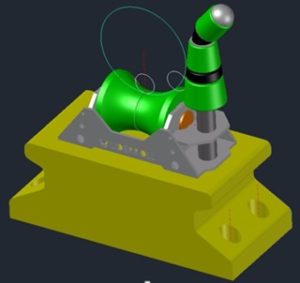

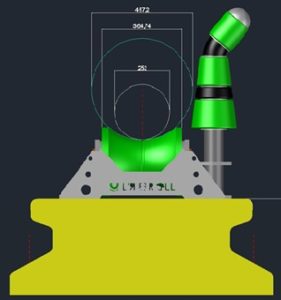

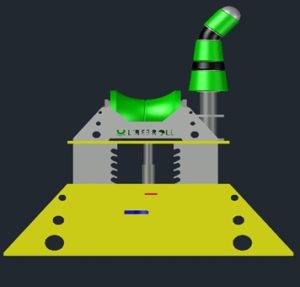

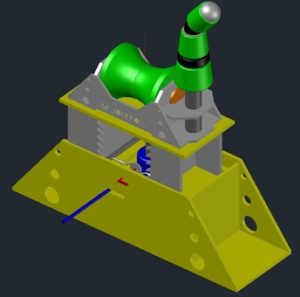

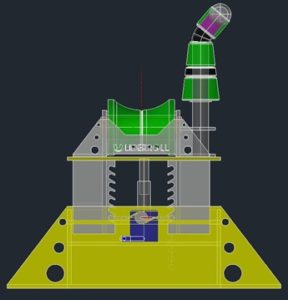

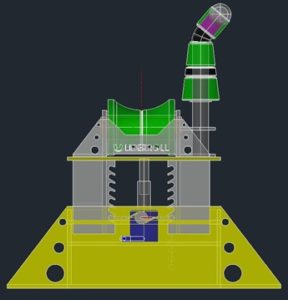

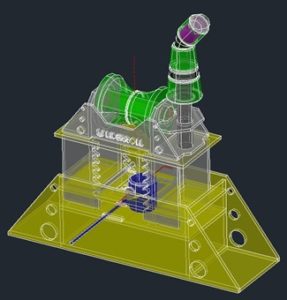

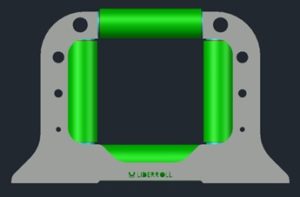

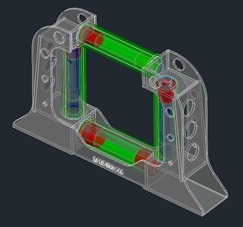

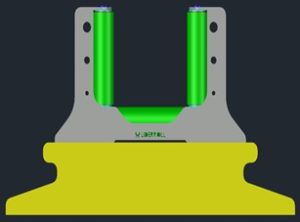

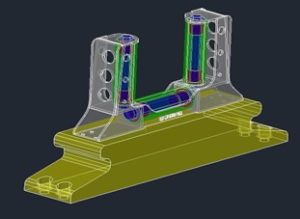

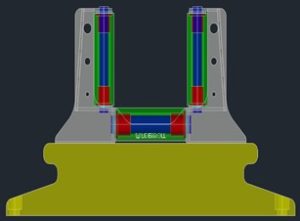

NOTE – Petronotícias readers can learn more about this method is through the Featured Video, already posted on our website. See the drawings of some products designed by the company’s development team below.

This creation by Liderroll has already been patented in several countries and may be presented at Rio Pipeline or even at a special event in Calgary, Canada, with the participation of the ASME – America Society Mechanical Engineering. Liderroll is the only Brazilian company awarded by ASME for the creation of a revolutionary pipeline launching method in confined environments (see the prize in the photo on the right): a technology that will be used to launch pipelines and pipelines in tunnels that are under construction in several countries. This method is already approved by the companies responsible for pipeline projects that are under construction in Canada and Turkmenistan.

The President of Liderroll, Paulo Fernandes, spoke with Petronotícias about the creation of this new technology:

– We receive customer inquiries, but we always work wanting to exceed expectations, creating a product, always above and beyond the customer’s request. When we see that the business deserves a paradigm shift, Liderroll continues to study at its own risk, as is the case with the archaic and highly dangerous methodology of the current spool bases here in Brazil and around the world. In this case, we end up revolutionizing the construction and the methodology. Everything automated, without human presence, independent of the weather, independent of everything. And still using its own generation of energy through solar panels. Today’s methods seem like they were developed during the time of the Vikings.

– How is the method currently used?

– All spool bases in the world use a rudimentary method to move the stalks, columns with excavators, increase the stress level of the pipe,  increasing the risk of weld fatigue in the joints, damaging the coating, risk of accidents, etc. When I was an employee of Petrobrás, we already had an accident with death here in Brazil in a spool base. A length of tube was lowered on the abdomen of a collaborator, who died asphyxiated. He could not breathe because of everything on top of him. The instability of the ground where the excavator was moving the tractors contributed a lot. Today, due to the strictness of the QSMS oversight bodies, spool base operators in Brazil will most likely be required to present a safer method of operation. Also, the one that is currently used increases the risk of accidents and the very material used, steel pipes, can cause a fatal risk. In the operation that Liderroll has idealized, everything is automated. It removes humans from the job site. The system consists of rolling bridges operated from a control room, independent of rain, lightning, wind, and fuel storage. All of the problems become eliminated. Energy is generated by solar energy cells

increasing the risk of weld fatigue in the joints, damaging the coating, risk of accidents, etc. When I was an employee of Petrobrás, we already had an accident with death here in Brazil in a spool base. A length of tube was lowered on the abdomen of a collaborator, who died asphyxiated. He could not breathe because of everything on top of him. The instability of the ground where the excavator was moving the tractors contributed a lot. Today, due to the strictness of the QSMS oversight bodies, spool base operators in Brazil will most likely be required to present a safer method of operation. Also, the one that is currently used increases the risk of accidents and the very material used, steel pipes, can cause a fatal risk. In the operation that Liderroll has idealized, everything is automated. It removes humans from the job site. The system consists of rolling bridges operated from a control room, independent of rain, lightning, wind, and fuel storage. All of the problems become eliminated. Energy is generated by solar energy cells

– And what about the cost of a vessel that is capable of launching those pipes?

– That’s one of the highest costs. Often the ship slopes (photo on the left), takes seven, eight days carrying. In that time the sea can turn. The maritime conditions, the swell has changed, the wind has changed, and it cannot go out to sea and misses its time window. All of this is costly. Our method requires a change of thinking, of productivity. Obviously, the initial cost may be a little higher, but beyond the CAPEX, the OPEX savings pay off handsomely. Everything automated. Your planning can follow without risk of loss — all clean and functional.

– Are there many companies in the world that own spool bases?

– Not really. Not many, but I believe that one of these companies will take notice of our method and ask themselves: should I move forward in technology to do this? Of course, yes. They are companies accustomed to this, with the technical advance. With innovations, with automation. Only the great and good ones who act with civil seriousness and excel by technical, social, and environmental responsibility. I could cite companies like Saipem, Subsea 7, McDermott, and others, which will certainly come onboard when they see the thing take off. Norwegian, Dutch, Scottish companies. Only those who can not see the future, the technology, will be left out. So I am sure that companies with these characteristics will be interested in the economics of our technology, as is the case with our pipeline launching technology in tunnels.

– Not really. Not many, but I believe that one of these companies will take notice of our method and ask themselves: should I move forward in technology to do this? Of course, yes. They are companies accustomed to this, with the technical advance. With innovations, with automation. Only the great and good ones who act with civil seriousness and excel by technical, social, and environmental responsibility. I could cite companies like Saipem, Subsea 7, McDermott, and others, which will certainly come onboard when they see the thing take off. Norwegian, Dutch, Scottish companies. Only those who can not see the future, the technology, will be left out. So I am sure that companies with these characteristics will be interested in the economics of our technology, as is the case with our pipeline launching technology in tunnels.

– Is there much demand for this tunneling technology?

– I started with it in 2009, and today, ten years later, the world has already become aware. The industry saw what we did here in Brazil; that it is possible to save time in launching pipes in tunnels, and it was a hit. It is now an international reality, participating in large international projects. We are present in 19 countries, with seven projects under active study and four jobs about to close, in the United States, Jordan, Saudi Arabia, and the United Arab Emirates.

– So it was this the case with the spool base?

– What I can say is that Liderroll received an inquiry for a simple roller, but our vision is to serve our customers in the best way possible. We go  beyond their expectations. This is our motto. We invest money, time, and involve ourselves with passion in the projects to always surpass. See, following our philosophy, we came up with a new patent that will amaze the subsea market. Before, we were stuck in terrestrial pipelines, and now we have a new patent for constructive philosophy of spool bases, which tends to gain a lot of space in the international market.

beyond their expectations. This is our motto. We invest money, time, and involve ourselves with passion in the projects to always surpass. See, following our philosophy, we came up with a new patent that will amaze the subsea market. Before, we were stuck in terrestrial pipelines, and now we have a new patent for constructive philosophy of spool bases, which tends to gain a lot of space in the international market.

Increasing the quality, decreasing the execution time, giving more peace of mind, if there is joint repair. The loading time of the ship will decrease significantly, with the trips of these ships being made with a shorter time, taking advantage of a better sea condition, a good sea window, going back and forth more times, being able to have a loading load of 8 at least 24 kilometers in stand by. Make a reservation. It can work with different diameters within those 24 kilometers. It is a revolution in basic building methods. From stretches of tubes being loaded onto the ship, Jay Lay, Wheel Lay, whatever.

– How is Liderroll facing the phase which the oil and gas industry in Brazil is going through?

-Even in this bad phase, we stand firm for our purposes. Even after all the turmoil we’ve been through, the market is going through, we keep creating and having capacity and passion for engineering development. This new patent is an example of this. Let’s revolutionize. From the second half, in August, we will begin the international process of its demonstration. We’re working on a schedule. We already have already scheduled a visit to Europe to demonstrate to the big players. My expectation is that in three years, the constructive mindset will be different. There is no way that large and serious companies will not see these gains and benefits. So as the ancients say: people pass and companies stay. Everything we do, we do for the country, for our oil & gas community, for the big and serious companies; not for the career managers who only look at the moment and their bonuses.

-Even in this bad phase, we stand firm for our purposes. Even after all the turmoil we’ve been through, the market is going through, we keep creating and having capacity and passion for engineering development. This new patent is an example of this. Let’s revolutionize. From the second half, in August, we will begin the international process of its demonstration. We’re working on a schedule. We already have already scheduled a visit to Europe to demonstrate to the big players. My expectation is that in three years, the constructive mindset will be different. There is no way that large and serious companies will not see these gains and benefits. So as the ancients say: people pass and companies stay. Everything we do, we do for the country, for our oil & gas community, for the big and serious companies; not for the career managers who only look at the moment and their bonuses.

SEE THE PICTURES OF SOME PARTS DESIGNED BY LIDERROLL:

publicada em 30 de maio de 2019 às 3:59

publicada em 30 de maio de 2019 às 3:59

Hi my name is Joe Arrante. I am with PolySil Quality Casting Inc. We do cast Polyurethane, Machine and fabrication work. We supply bearings and other incidentals. We have supplied frames & rollers to many Spool Bases.I am trying to find out how to contact your procurement