CONSTRUCTION ON A SEVEN-KILOMETER TUNNEL BENEATH LAKE MICHIGAN FOR THE LINE 5 PIPELINE TO BEGIN EARLY NEXT YEAR

The government of Michigan, in the United States, is still discussing, with Canadian operator Enbridge, the controversial Line 5 pipeline project, which is currently submerged in the lakebed of Lake Michigan. On June 7th, another round of discussions with the involving the local community, the Michigan government, the Mackinac Straits Corridor Authority (MSCA), and the Canadian company which owns the pipeline will take place. Remembering that, a little over two years ago, a ship’s anchor hit the existing pipeline, built around 70 years ago, nearly causing an unprecedented environmental disaster in the region. Enbridge has decided to build a tunnel under the lake and install a new replacement pipeline in it, which would prevent such an accident. However, Enbridge has not yet decided which company will perform the construction. The underwater tunnel will be almost seven kilometers long and will house the new 30-inch pipeline, which will replace the current pipeline.

The government of Michigan, in the United States, is still discussing, with Canadian operator Enbridge, the controversial Line 5 pipeline project, which is currently submerged in the lakebed of Lake Michigan. On June 7th, another round of discussions with the involving the local community, the Michigan government, the Mackinac Straits Corridor Authority (MSCA), and the Canadian company which owns the pipeline will take place. Remembering that, a little over two years ago, a ship’s anchor hit the existing pipeline, built around 70 years ago, nearly causing an unprecedented environmental disaster in the region. Enbridge has decided to build a tunnel under the lake and install a new replacement pipeline in it, which would prevent such an accident. However, Enbridge has not yet decided which company will perform the construction. The underwater tunnel will be almost seven kilometers long and will house the new 30-inch pipeline, which will replace the current pipeline.

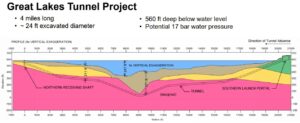

THE TUNNEL MAP SHOWS THE SLOPE AND SLOPE OF THE PIPELINE. USING STEEL CABLE TO PULL THE PIPE WILL BE IMPOSSIBLE

In the debates held during past public hearings, Enbridge presented the technology developed by Brazilian company Liderroll, already internationally established, as the best way to lay the oil and gas pipelines in confined environments such as tunnels, which was approved by the local government and the Michigan society that participated in the discussions. Liderroll has a lot of experience in this topic, having already designed, manufactured, built, and launched four different lines in two long tunnels. One, 38 inches in diameter, into the GASDUC III Tunnel, in Rio de Janeiro, and three pipelines of different diameters inside the GASTAU Tunnel, under mountains. Today, the responsibility for these two tunnels lies with the operating company NTS.

By the end of this year or early next year, the choice and decision of the technology to be used to launch the pipeline inside the tunnel under the lake will be known. At the moment Enbridge is studying proposals.

ENBRIDGE’S INSPECTION OF THE SUBMERGED PIPELINE

Liderroll owns the patents to this pipeline installation technology in both the United States and Canada. Enbridge, which demonstrated the Brazilian technology for the Michigan government, is now presenting on its website, a different way of constructing the pipeline in question, which has never been tested in a tunnel featuring a very rugged profile (pictured) and quite long, with an estimated water pressure of more than 17 BAR, at a depth of around 170 meters, and with the extra challenge of this tunnel having a long stretch downhill and another uphill. Without motorized driving rollers and special supports, there is most likely no other technology capable of solving this problem. This project will be in charge of a construction company, which has not yet been chosen, according to the company’s spokesman, Ryan Duffy, from whom Petronotícias received an information update for our readers.

– How is Enbridge’s relationship with the Michigan government?

-We have been working well with several Michigan state agencies and staff at those agencies on the permitting process for the tunnel project. We have received a permit from the Michigan Department of Environment, Great Lakes and Energy (EGLE) and are waiting on approval from the Michigan Public Service Commission.

Has the company for the construction of the tunnel already been hired?

company for the construction of the tunnel already been hired?

-No, we have put out a request for proposals for the project and will be reviewing bids from companies interested in constructing the tunnel. We hope to select a company by the end of this year or early 2023.

-Has the Brazilian company, which already has a great deal of experience in this type of work, been contacted?

-It will be up to the construction company selected for the project to choose its subcontractors for the project.

-When does Enbridge intend to start building the tunnel?

-The permitting process is the driver of the timeline for the project. When we receive all permits we will begin construction. The construction process itself will take approximately four years.

-The permitting process is the driver of the timeline for the project. When we receive all permits we will begin construction. The construction process itself will take approximately four years.

-Will the company launch only one duct line inside the tunnel or will it have a reserve line, for any eventuality?

-There will be a 30-inch new pipeline inside the tunnel which will replace the current section of Line 5 in the Straits. There will also be room in the tunnel for other utilities.

-Has Enbridge maintained inspection and maintenance on the current Line 5?

-All of our inspections and testing of Line 5 tells us it is in very good condition. We are constantly inspecting the pipeline both on the inside and externally. Also, our federal regulator the Pipeline Hazardous Materials Safety Administration has said time and time again that the line is fit for service.

federal regulator the Pipeline Hazardous Materials Safety Administration has said time and time again that the line is fit for service.

-On June 7 there will be a new round of negotiations with the Michigan government. What is the expectation of Enbridge?

-On June 7 there is a meeting of the Mackinac Straits Corridor Authority. This is a routine meeting, I have not seen the agenda yet for the meeting so I’m not sure what is planned.

Enbridge will wait until early next year to announce the victorious contractor. The company will have to build a seven-kilometer tunnel below the lake bed, a rocky stretch under the Straits of Mackinac, which will house a new section of the Line 5 pipeline. The company still needs permits from the Michigan Public Service Commission and the U.S. Army Corps of Engineers. Petronotícias also talked to the CEO of Liderroll, Paulo Fernandes, about the subject. He said that he knows the subject well and that it will be very possible that the company that is contracted will use Liderroll’s knowledge in this job:

Enbridge will wait until early next year to announce the victorious contractor. The company will have to build a seven-kilometer tunnel below the lake bed, a rocky stretch under the Straits of Mackinac, which will house a new section of the Line 5 pipeline. The company still needs permits from the Michigan Public Service Commission and the U.S. Army Corps of Engineers. Petronotícias also talked to the CEO of Liderroll, Paulo Fernandes, about the subject. He said that he knows the subject well and that it will be very possible that the company that is contracted will use Liderroll’s knowledge in this job:

– Well, first of all, I want to say that we found it strange that, in 2019, the video released on Enbridge’s website used 100% of our technology, including the exact geometry of our parts, and even our green and yellow colors of Brazil. All this to present to the population and local politicians how the pipeline would be built, launched, and how safe it would be away from the lake waters inside the tunnel. We were surprised because it was a video with our technology that was taken as a reference and technical basis in the presentations of the public hearings, which led to the creation of the Public Act by the Michigan Senate and signed by the governor of the time.

PAULO FERNANDES PRESENTS HIS TECHNOLOGY USED BY ENBRIDGE AT PUBLIC HEARINGS

Not only does the video clearly show our solution, but the technical reports and documents delivered to the authorities cited photos of the success of the GASTAU tunnel work in Brazil. And now they show another concept that dribbles everything that was studied by the consultancy at the time. And we do not agree with this. (https://youtu.be/v8TV8_-n55Y ) – Click here to see this presentation.

– When you became aware of this, what did you do?

– We immediately sent emails to Enbridge warning about this and showing that our solution would speed up the construction and guarantee performance. I heard that they would pull the pipe with a steel cable. But this is practically impossible, because it is a seven-kilometer tunnel, with a steep slope that needs traction control, precise positioning for the welds and brakes to hold the entire downhill column, and the second part of the tunnel is a very steep and heavy climb for any kind of traction system. Our technology has already shown that it is very efficient and safe, that in the GASTAU tunnel, we launched a 28-inch line and brought the deadline forward by two months. Imagine the savings. After that, we launched two smaller lines on top of this 100% pressurized pipeline, which are all in operation.

– Is it possible to launch another line in tunnels like this?

– Is it possible to launch another line in tunnels like this?

– Absolutely, as I said. We have launched two more lines with the live pipeline. It is a five-kilometer tunnel. If you are standing at the entrance, you can’t see the end of the tunnel. In Michigan, the tunnel is almost seven kilometers long. Imagine! We can use our know-how, methodologies, and technology to make the construction project possible. And, most importantly, avoid accident risks, both in the construction and in the permanent operation over the years. Our technique is unique in the world and the GASDUC III tunnel alone has been in use without any maintenance since 2009.

– Have you spoken to the Enbridge people about this?

– Well, besides the emails we used DHL to deliver a complete printed set of materials. In this content, we draw attention to serious technical and constructive problems, and we have even taken the initiative to send the preliminary design and the conceptual project, which confirms all our warnings about the risks and the best solution to be adopted. This warning was sent to the CEO of the company, heads of engineering, and a few other people. Ethically we have done our duty and the warning was given to avoid all kinds of damage. Let’s see now what they will decide. Will they try to execute the new project that was presented to the Michigan authorities, which contains the irrefutable technical risks that we documented, to the detriment of Liderroll’s technology, recognized, tested, and awarded worldwide?

and we have even taken the initiative to send the preliminary design and the conceptual project, which confirms all our warnings about the risks and the best solution to be adopted. This warning was sent to the CEO of the company, heads of engineering, and a few other people. Ethically we have done our duty and the warning was given to avoid all kinds of damage. Let’s see now what they will decide. Will they try to execute the new project that was presented to the Michigan authorities, which contains the irrefutable technical risks that we documented, to the detriment of Liderroll’s technology, recognized, tested, and awarded worldwide?

publicada em 25 de maio de 2022 às 3:59

publicada em 25 de maio de 2022 às 3:59